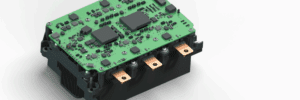

ROHM and Schaeffler begin mass production of high-voltage SiC inverter brick for EVs

ROHM and Schaeffler have announced the start of mass production for a new high-voltage inverter brick featuring ROHM’s silicon carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) bare chips. Schaeffler says the device is designed for a major Chinese electric EV manufacturer.

The inverter brick supports battery voltages significantly greater than the typical 800 V standard and can deliver root mean square (RMS) currents up to 650 A. These capabilities enable a more compact but powerful power electronics module. According to ROHM, the inverter brick’s modular and scalable design is central to its easy integration into a variety of inverter architectures, supporting rapid deployment in vehicle platforms using so-called X-in-1 powertrain approaches. The brick integrates a power module for pulse width modulation, a DC link capacitor, DC link and integrated cooling.

Additionally, it features a DC boost function, which allows vehicles with 800-volt systems to charge at 400-volt charging stations while maintaining the higher charging speed associated with 800-volt infrastructure.

ROHM notes that its fourth-generation SiC technology substantially improves efficiency and performance for EVs, strengthening the role of silicon carbide power semiconductors in modern automotive applications. The partnership between Schaeffler and ROHM, established in 2020, aims to secure improved capacity and supply of energy-efficient SiC power semiconductors.

Source: ROHM

Source link