Optimizing the thermal management ecosystem in EV batteries

Continued optimization of battery design means addressing thermal runaway and other issues. Pressure-sensitive adhesive (PSA) tapes may be an important part of the solution.

By Max VanRaaphorst—Market Manager, Energy Storage for Avery Dennison North America.

This is a dynamic time for the electric vehicle (EV) marketplace. According to an April 2025 report by Cox Automotive, EV sales rose 11.4% in the first quarter of 2025 compared to the first quarter of 2024. Many long-term forecasts predict continued double-digit growth.

The near-term outlook for the industry, however, is volatility. As of this writing, the Trump administration’s tariff plan remains in flux. Whatever their final form, tariffs seem likely to stir the global supply chains that manufacturers depend on.

Regardless, engineers tasked with making EV batteries safer, more durable, and more energy-dense must remain focused on the task at hand. Truly transformative technologies, such as solid-state batteries, are still years off. So, continued progress means further optimization of current technology platforms. Pressure-sensitive adhesive (PSA) tapes, integrated with functional materials, are a versatile, easy-to-use, and cost-effective material solution for many of today’s EV battery engineering challenges.

The thermal management ecosystem

A key challenge in this story of optimization is that of thermal management.

A battery is a complex ecosystem requiring temperature regulation for optimal cell performance during normal use as well as during extreme events. At the most basic level, that means cells should be warmed when they’re too cold and cooled when they’re too warm.

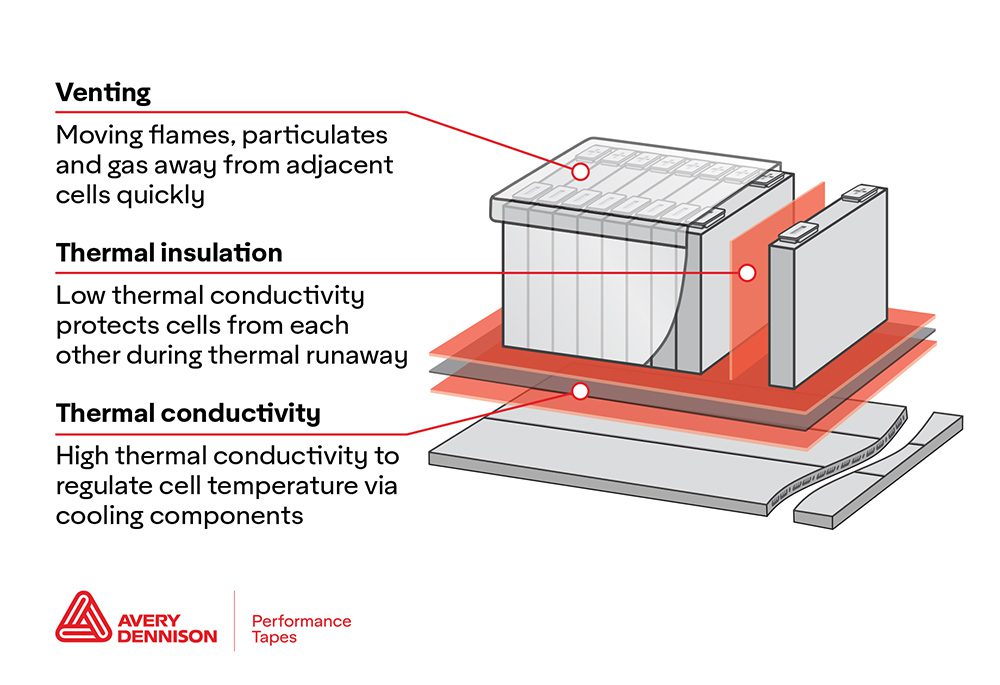

Batteries thus have three types of thermal requirements:

1. Thermal insulation

Low thermally conductive (insulating) materials are used to protect normally operating cells from overheating, thus preventing thermal runaway events.

2. Thermal conductivity

High thermally conductive materials, such as thermal interface materials (TIMs), are used to connect cells to cooling components and facilitate heat transfer.

3. Venting

Venting strategies allow hot gases to escape a malfunctioning cell while protecting adjacent cells. These strategies can incorporate various thermal materials.

To understand thermal conductivity … go for a hike in the woods

Compare the idea of thermal conductivity to a hike in the woods. Imagine trying to bushwhack through a dense forest of trees, low-lying scrub, roots and rocks, and perhaps some mud. It’s difficult, you’re breathing hard, sweating and maybe cursing a bit! Now compare that to a walk on a flat, well-maintained, tree-lined trail. It’s easier and probably more enjoyable. From heat’s perspective, a low conductivity material is like that dense forest — difficult to traverse. A high conductivity material is the gentle trail.

Another important consideration is the length of the hike itself. A short hike through a dense forest may not be much of an obstacle. It’s the long slog that ultimately slows you down.

That brings us to PSA tape solutions for thermal management. Tapes, by design, are very thin. So while they don’t tend to offer high thermal conductivity, they do offer just a short path for heat to travel. But due to their tremendous versatility, tapes can also be integrated with low thermal conductivity materials, thus making them suitable for a wide range of thermal management applications within a battery pack.

Thermal runaway barrier solutions

Thermal runaway starts when an overheating cell combusts. That fire grows to the point at which hot gases and materials burst from the cell. The escaping matter causes other cells to overheat, catch fire and burst in turn. A module-level thermal runaway event can then spread to other modules in a pack, causing complete destruction of the battery pack and likely the vehicle.

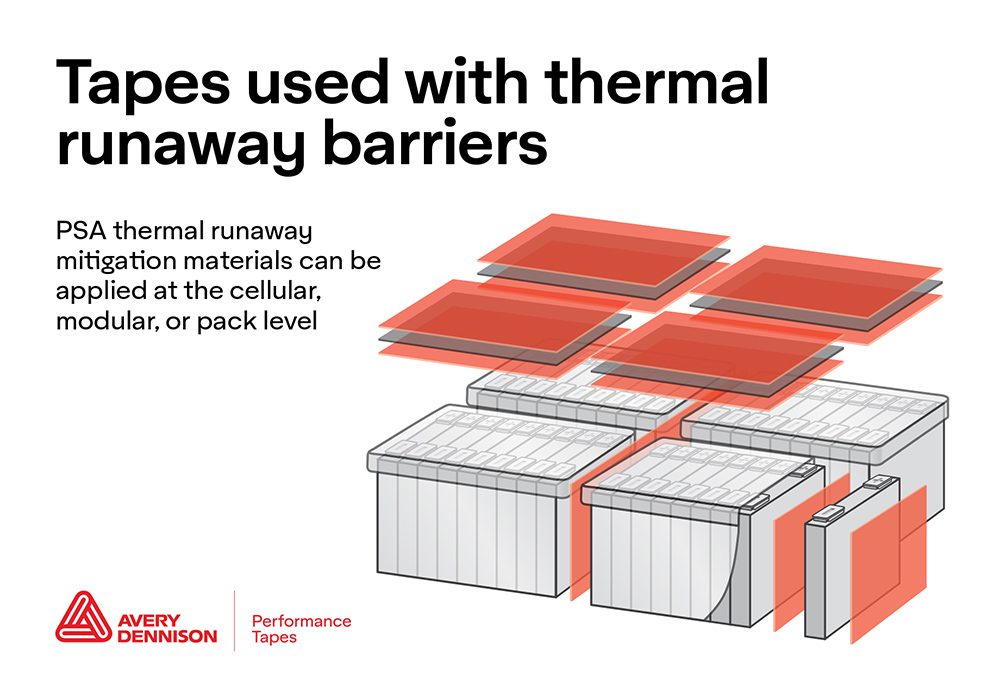

Tapes can be used to encapsulate insulating (low heat conductivity) barrier materials, such as mica, ceramic paper or aerogels. These can then be placed between cells, modules, and/or on the inside of the pack lid. Because of tapes’ thin profiles, they’re an ideal choice for these narrow spaces — providing the necessary bond while allowing for the maximum possible thickness of the insulating material given the space constraints.

In some circumstances, these PSA-based solutions can prevent cell- or module-level thermal runaway propagation. But in most cases, they can at least slow the spread of thermal runaway, providing valuable time for passengers to exit the vehicle.

Thermal runaway venting solutions

As noted above, thermal runaway is underway when hot gases and materials erupt from a single cell. Cell manufacturers thus integrate venting strategies into their designs.

A vent is simply a port that allows hot, expanding gases and burning material to escape the cell’s confines, creating a more controlled pressure release. The problem lies in the fact that as those escaped rush through the module, they can infiltrate other cells through their vent ports, and thus initiate a thermal runaway event.

What’s needed is a venting strategy that allows that pressure release while protecting healthy cells from those hot gases and materials. Again, PSA tapes offer an elegant solution: In this case, it’s tapes with an anisotropic carrier—just one side of the tape offers flame resistance.

These PSA tapes are applied to battery cells during assembly, covering the vent ports. The anisotropic carrier then allows flames to escape through the port of a burning cell. But as the flames then circulate through the module, the flame-retardant side of the tape protects the vent ports of healthy cells.

PSA-based anisotropic tapes can help protect healthy cells and inhibit thermal runaway.

Flame retardance isn’t permanent. Eventually, the tape is compromised, and flames can affect healthy cells. But again, this is about mitigating and delaying full thermal runaway, and giving passengers valuable time for a safe escape.

Dielectric protection solutions

Electrical arcing in a high-voltage environment can often lead to fire, and thus is another issue that can affect a battery ecosystem’s thermal management. Again, PSA tapes are stepping up to the challenge.

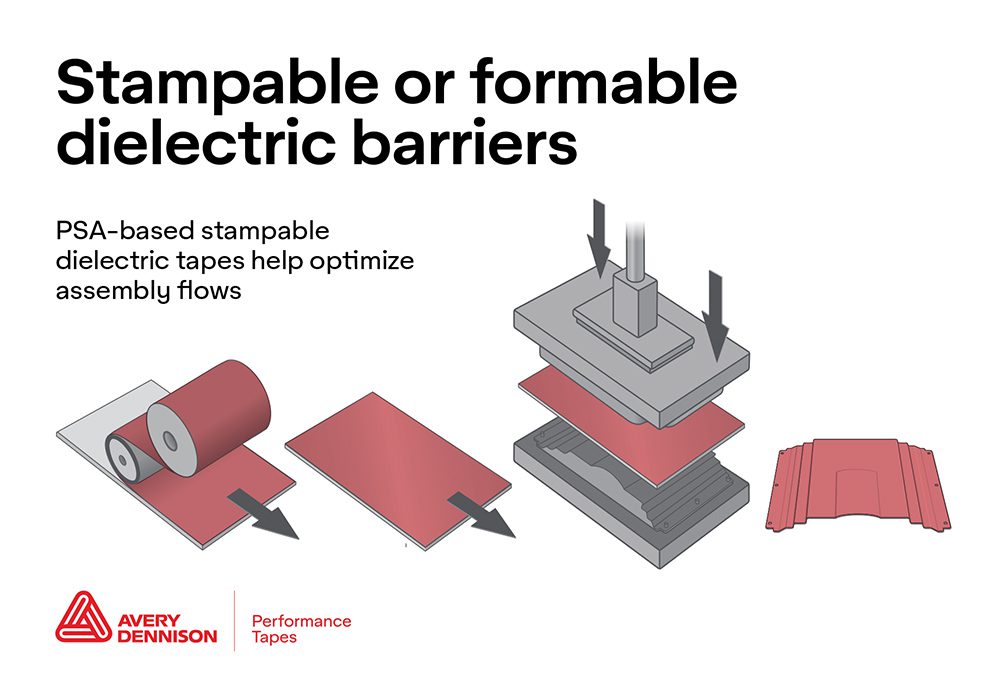

Polymer film tapes can be used within the pack and module for bonding or to encapsulate critical parts. These tapes offer high dielectric strength per unit thickness and tend to inhibit heat flow, making them a preferred alternative to many traditional dielectric coatings.

A new PSA tape technology is a dielectric tape that can be applied to flat metal blanks prior to stamping and forming. It’s an easy-to-use solution that optimizes both dielectric strength and assembly flows, as it eliminates curing and cleaning, and other processes needed for traditional coatings. Avery Dennison has recently published a whitepaper explaining how stampable dielectric PSA tape technology can benefit manufacturers.

PSA tape solutions are available now

All of the PSA tape solutions discussed in this article are currently available. In fact, the Avery Dennison EV Battery Portfolio contains a wide range of PSA tape-based solutions engineered to help manufacturers address issues such as thermal runaway and dielectric protection. And these tapes are easy to incorporate into either manual or automated assembly processes, helping EV battery manufacturers optimize both workflow and design.

Tape solutions can be cut and stamped to spec and provided at scale by local converters. These third-party providers work closely with Avery Dennison and the battery manufacturer to ensure the right solutions are provided at the volumes needed, even in a volatile time for the automotive industry.

A bright future for EVs

Whatever volatility the near term might hold, the future is bright for EVs. By using solutions such as PSA tapes, manufacturers can be confident their products will meet consumers’ needs for safety, reliability and durability.

Source link