High-potential testing for EVs: why reed relays raise confidence in insulation and safety

EV platforms live at the intersection of high voltage, high power and strict safety requirements. From battery packs and traction inverters to DC fast chargers and cable harnesses, engineers must prove that insulation is sound during development and at end-of-line. That is the role of high-potential testing. In a withstand test the product is stressed above normal operating voltage and leakage is measured. In a breakdown test the voltage is increased until insulation fails so that safe design margins can be set. Both require precise control of kilovolt sources, very low leakage measurement and safe discharge paths.

This article shows how to build reliable hipot stages for EV testing and why high-voltage reed relays are a strong fit for the switching and safety functions inside those stages.

Where hipot fits in the EV lifecycle

Battery modules and packs

Verify isolation from chassis, check coolant ingress risk, validate contactor assemblies and pre-charge networks. End-of-line stations typically perform DC withstand tests and store leakage results as a baseline for field service.

Traction inverters and DC-link assemblies

Validate the isolation barrier between the high-energy DC bus and control electronics, then repeat after thermal cycling or vibration stress.

Onboard chargers and DC fast chargers

Confirm isolation from the AC grid and between power stages. For megawatt-class systems, safe discharge after a test step is essential before operators can connect the next unit under test.

High-voltage wiring harnesses and connectors

Cable hipot checks for pin-to-pin shorts and pin-to-shield leakage, often across hundreds of nets through a switching matrix.

These use cases push the same core requirements on the hipot station: apply and measure at kilovolt levels, limit fault energy, sequence tests safely, minimise test time, and keep leakage measurement trustworthy.

Why the switch technology matters

Inside most hipot rigs you will find a programmable HV source, measurement and protection hardware, and a bank of switches that route the source and meter to the unit under test or to a discharge load. The switches shoulder several jobs at once. They must:

- withstand high open-circuit voltage without breaking down

- switch the desired voltage and energy when required

- contribute little leakage or parasitic capacitance

- isolate control electronics from the HV domain

- operate quickly and repeatably over long duty cycles

Electromechanical relays are affordable but their open-air contacts limit practical switching voltage and standoff. Solid-state relays are fast and compact, yet introduce non-linear leakage and higher off-state capacitance that can mask real leakage in the device under test. High-voltage reed relays solve a different set of problems. The contacts are sealed in an inert vacuum, so they tolerate higher electric fields in a small package and deliver extremely low off-state leakage with very low parasitics. The coil is galvanically isolated from the signal path, which protects control electronics. Operate times are short, typically under a millisecond, which helps keep cycle time down.

In short, the switch behaves more like a near-ideal open or closed conductor, which is exactly what you want when measuring microamp or nanoamp leakage.

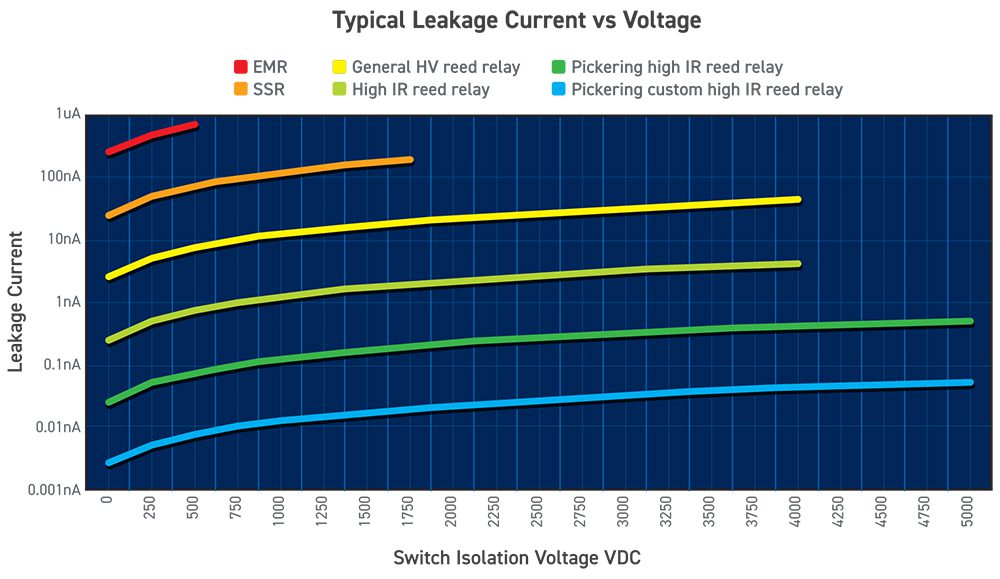

This graph shows a comparative plot of leakage current versus isolation voltage for several switch classes. Traditional EMRs rise early and are limited by their lower standoff. Typical high-voltage SSRs hold longer but still leak in the microamp region as voltage climbs. Instrument-grade reed relays maintain much lower leakage at higher voltages because insulation resistance is orders of magnitude higher, into the 10¹² to 10¹³ ohm range for standard devices and up to 10¹⁴ ohm in custom builds. For battery, inverter and charger hipot, that difference is the gap between a clean pass and a false failure.

Architecting a hipot stage with reed relays

A practical EV hipot station will include several relay-controlled paths:

- Source routing. Select the desired voltage domain, for example pack positive to chassis, pack negative to chassis, or pin-to-pin on a harness. Reed relays with high standoff ratings serve as the isolation elements here.

- Measure path. Switch the meter across the device under test or to a reference load for self-check. Low leakage and low capacitance in the relay help preserve measurement fidelity.

- Discharge and bleed. After a test step, route a resistor across the output so stored energy is removed before the operator proceeds. Using a dedicated reed relay for this function creates a predictable, safe discharge path every time.

- Protection and interlock. Separate relays can enforce permissives, for example open the source path instantly if limit current is exceeded and latch the system until the discharge completes.

Because reed relays are compact and magnetically screened, many channels can be packed on a single board to build scalable harness or pack fixtures. If you need Kelvin measurements elsewhere in the station, two-pole devices reduce the channel count for four-wire connections.

Picking the right device: what to look for

When you choose relays for hipot switching, match the specification to the job:

- Minimum standoff voltage. This is your open-contact survival number. For EV and charger work, devices with 5 kV, 10 kV or 20 kV ratings give comfortable headroom.

- Maximum switching voltage and power. For breakdown tests and for controlled discharge, ensure the relay can switch the intended voltage and energy without contact erosion.

- Switch-to-coil isolation. Protects your controller if the HV path faults. Pickering’s customizable Series 600 can be configured for up to 25 kV switch-to-coil isolation.

- Insulation resistance. Higher is better for leakage fidelity. Standard Pickering HV relays are tested to greater than 10¹² ohm, and custom parts can reach greater than 10¹⁴ ohm.

- Operate and release times. Faster operate reduces dwell, faster release shortens the discharge-to-ready interval.

- Physical format and shielding. Internal mu-metal shields allow side-by-side packing with minimal magnetic interaction, which matters when you scale to large matrices.

Product options that map cleanly to EV hipot

You can build most EV hipot matrices from a small set of families:

- Series 63 and the customizable Series 600, for the highest isolation demands. Up to 20 kV standoff with switching up to 12.5 kV, 200 W max. Series 600 adds modular options for voltage, coil, shielding and mounting, and can be configured for up to 25 kV switch-to-coil isolation. Both series also include changeover options up to 2.5kV switching and 5kV standoff. Good fits include pack and charger isolation tests, inverter barrier validation and long-duration burn-in where standoff margin helps.

- Series 60 and 65, for high-voltage routing where space is tight. Up to 12.5 kV switching and up to 15 kV standoff, with switch currents up to 3 A at 50 W and carry currents up to 3.5 A. Often used in cable and harness hipot fixtures.

- Series 104, compact devices with 5 kV standoff and 1.5 kV switching. Useful as measurement selectors, discharge path control, or safety interlocks inside the rig.

- Series 67 and 68, high-power options that bring 200 W switching into a dense package with up to 10 kV standoff and 7.5 kV switching. Helpful where you need higher current discharge networks or stress steps. They also have a unique design to enable higher density packing, whilst still maintaining appropriate distances between pins. Changeover options are also available up to 2.5kV switching and 5kV standoff.

- Series 119 and surface-mount Series 219, for compact boards that still need up to 3 kV standoff and 1 kV switching. These enable dense multi-channel fixtures that slide into modular testers.

If your topology calls for two-pole parts, Pickering also offer a wide range of 2-pole configurations to support Kelvin connections and reduce channel count.

Design tips that save time on the bench

- Think in energy, not only voltage. A 5 kV breakdown step into a capacitive load stores energy that must be discharged safely. Rate the discharge relay and resistor for both voltage and pulse energy.

- Guard your measurements. Use guarded layouts and high-resistance materials around the relay pins so leakage paths do not bypass your meter. Internal shields avoid the external clearances that can limit open-contact voltage in some designs.

- Sequence for operator safety. Interlock the source path with the discharge path and door switches. Use the relay’s fast operate and release times to shorten the safe-to-touch interval between DUTs.

- Validate at temperature. Leakage and standoff are temperature sensitive in many systems. Run a short design validation that sweeps temperature with your chosen relay set before freezing the BOM.

Closing the loop with production needs

EV programs live on throughput. Cycle time and uptime matter as much as headline voltage. Reed relays help on both fronts. Operate times can be sub-millisecond, so routing steps do not dominate the test. Mechanical life extends to millions or even billions of operations when used within rating, which keeps fixtures in service and reduces maintenance. Low coil power also helps thermal design in dense racks.

For engineers who need to standardize across platforms, the same relay families show up in pack hipot, charger isolation, inverter barrier checks and cable harness testers. That simplifies spares and documentation and lets you reuse known-good layouts.

Where to start

If you are building or refreshing an EV hipot station, a practical selection is one of the Series 63 or Series 600 devices for the main isolation paths, Series 104 for measurement and interlocks, and Series 67 or 68 for discharge control when higher power is required. For compact harness fixtures, look at Series 119 or 219 to keep density high. If you have a constraint that a catalog device does not meet, Pickering’s engineering team can tune coil voltage, shielding, pinout and isolation to match your design rules.

Have questions or want to review a schematic? Pickering’s expert reed relay engineers are happy to help select parts, discuss creepage and clearance on your board, and advise on discharge sizing and safety interlocks for your voltage and energy levels.

Contact: techsales@pickeringrelay.com

Source link